Every application is different, but they often have something in common with other applications. We normally consider helical guy anchor performance in different types of soil, but different underwater applications can also impact the service life of guy anchors.

Did you know that you can calculate an estimated service life for CHANCE® guy anchors? Knowing the effect that different types of water environments have on corrosion and structural steel loss, we can estimate the life in each application. This can be very helpful in determining the best product for your specific project.

Relating Service Life and Corrosion

Service life is defined as the estimated length of time it takes for 1/8” of material loss to occur on the solid steel shaft of a helical pile or anchor. Loss beyond that allows more possibility of failure. Corrosion is the degradation of a material due to reaction with its environment. For metals, the surface becomes oxidized, resulting in material loss over time. Given enough time, corrosion results in a reduction of the structural capacity of the metal. Eventually, it destroys enough of the structure’s strength that you could witness a failure.

Over the past 50 years, experience has shown that most helical anchors have a calculated service life that far exceeds the design life of the structure. That’s usually 50-75 years in the United States. Highly corrosive environments require additional protection for steel foundation products.

Different Types of Water Corrode at Different Rates

Which underwater or marine environment is most stressful to guy anchors? Seawater immersion is actually three times less corrosive than tidal or splash zones. Tidal areas can have very high corrosion loss rates, influenced by salt spray, breezes, topography and proximity. Seawater deposits protective scales on zinc when fully immersed. Zinc coatings from hot dip galvanizing steel provide the first layer of an elaborate protective system.

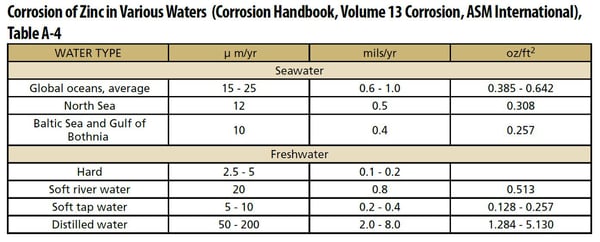

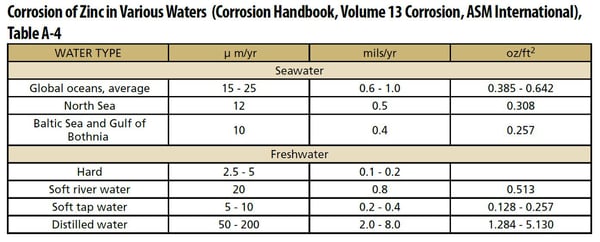

For freshwater applications, hard water is usually less corrosive than soft water, from a river or a tap. Hard water also deposits protective scales on the metallic surface. Distilled water causes even more aggressive corrosion than soft water.

Corrosion loss rates for zinc in various water types are generally known. You can find them in Table A-4 in the CHANCE Technical Design Manual.

Calculating Service Life

You can estimate the life of the zinc coating by dividing the amount of zinc deposited over a square area by the average zinc loss per area per year. Steel loss rates will vary based on site conditions, but can generally be assumed to be at least three times more than the zinc loss rate. Refer to the Technical Design Manual for more details.

To determine the shaft life of a helical pile or anchor, the steel loss is divided by the average loss per year. Then add the zinc life plus the shaft life to determine a total estimated service life of the pile shaft.

Find out more about these calculations, including examples, in our CHANCE catalog corrosion appendix. For assistance, contact your Hubbell sales representative.