What is Step and Touch Potential?

While performing energized or de-energized line work, there are many opportunities for a line worker to encounter differences in electrical potential. Opportunities could include working near bucket trucks, underground gear, overhead switches, or in substations. When a difference in potential occurs across a worker’s body, current begins to flow. This current flow can be very hazardous as it only takes 50 to 60mA to become possibly lethal. These differences in potential can be categorized as step and touch potential. Step potential is defined as a difference in electrical potential between a worker’s feet and touch potential can be between a worker’s hands or hands and feet.

Protecting Lineworkers from Step and Touch Potentials with CHANCE Equi-Mats

To reduce the hazards of step and touch potentials the worker can insulate and isolate or create an Equipotential Zone to minimize the current flow across the body. One of the ways to keep a lineworker in an Equipotential Zone is to use a bonding or grounding mat. In 1910.269 Appendix C, OSHA defines these mats as a temporarily or permanently installed metallic mat or grating that establishes an equipotential surface and provides connection points for attaching grounds.

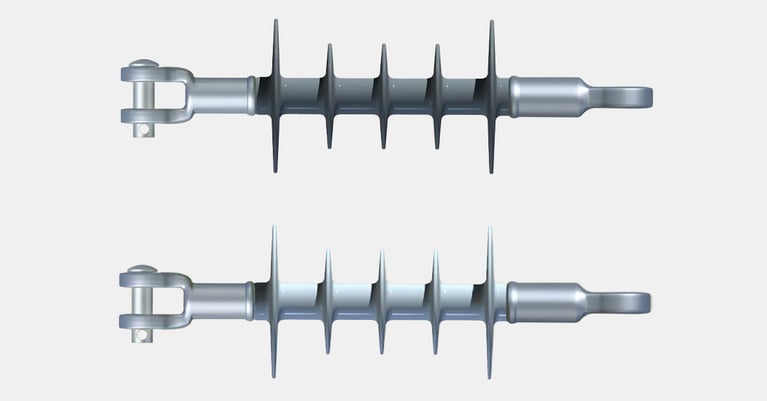

In order to meet the needs of OSHA 1910.269 Appendix C, CHANCE® offers a full line of Equi-Mats® that are designed, tested, and manufactured to the ASTM F2715 standard. These are available in standard orange and slip resistant black design and consist of a high-ampacity tinned-copper-braid cable sewn in a grid pattern onto a vinyl/polyester fabric. Offerings vary from 24” x 24” up to 120” x 120” and can be daisy chained to create a larger workspace. The Equi-Mats are available by themselves and in a kit with a bag and a ground set.

CHANCE Equi-Mats Use

CHANCE Equi-Mats can be used with grid side up or down, but they perform slightly better grid side up. Applications for the CHANCE Equi-Mats include standing on them in order to make cable terminations on transformers and in cubicles, open or close overhead air break switches, work on control boxes of regulators, reclosers, capacitors and pad mounted switches, and protect workers with booms around power lines and stringing operations.

Equi-Mats are designed to be stood on and can be easily visually inspected and resistance tested before each use. Other products such as dielectric footwear or overshoes can wear down over time and are both difficult to visually inspect and rarely electrically tested while in use. Rubber blankets are not designed as primary protection to be stood on in order to isolate line workers from ground potential.

Care, Maintenance, and Testing

CHANCE Equi-Mats should be visually inspected and resistance tested before each use. When visually inspecting the mat, the user should look for broken strands, loose connections, and damage to the metal braid. To resistance test per ASTM 2715, the DC milliohm resistance is measured corner to corner diagonally. The maximum acceptable resistance is 1.00 milliohm per foot. For example, a 10ft by 10ft Equi-Mat measures 14.14ft diagonally and should have a maximum resistance of 14.14 milliohms.

While not in use, the mat should be stored folded, preferably in a bag. If the mat becomes dirty during use, rinse with tap water. Harsh chemicals could damage the vinyl/polyester fabric backing.

In summary, CHANCE Equi-Mats are a great product to use to reduce step and touch potentials and keep line workers in an Equipotential Zone. Please make sure to always follow your company’s work practices and procedures.

Click here to browse the CHANCE Equi-Mats