- Hubbell Power Systems Blog

- Anchors

Anchors

Written by Tim Staelens

CHANCE brand anchors installation tools are critical to the construction of overhead electric and...

Written by Gary Seider

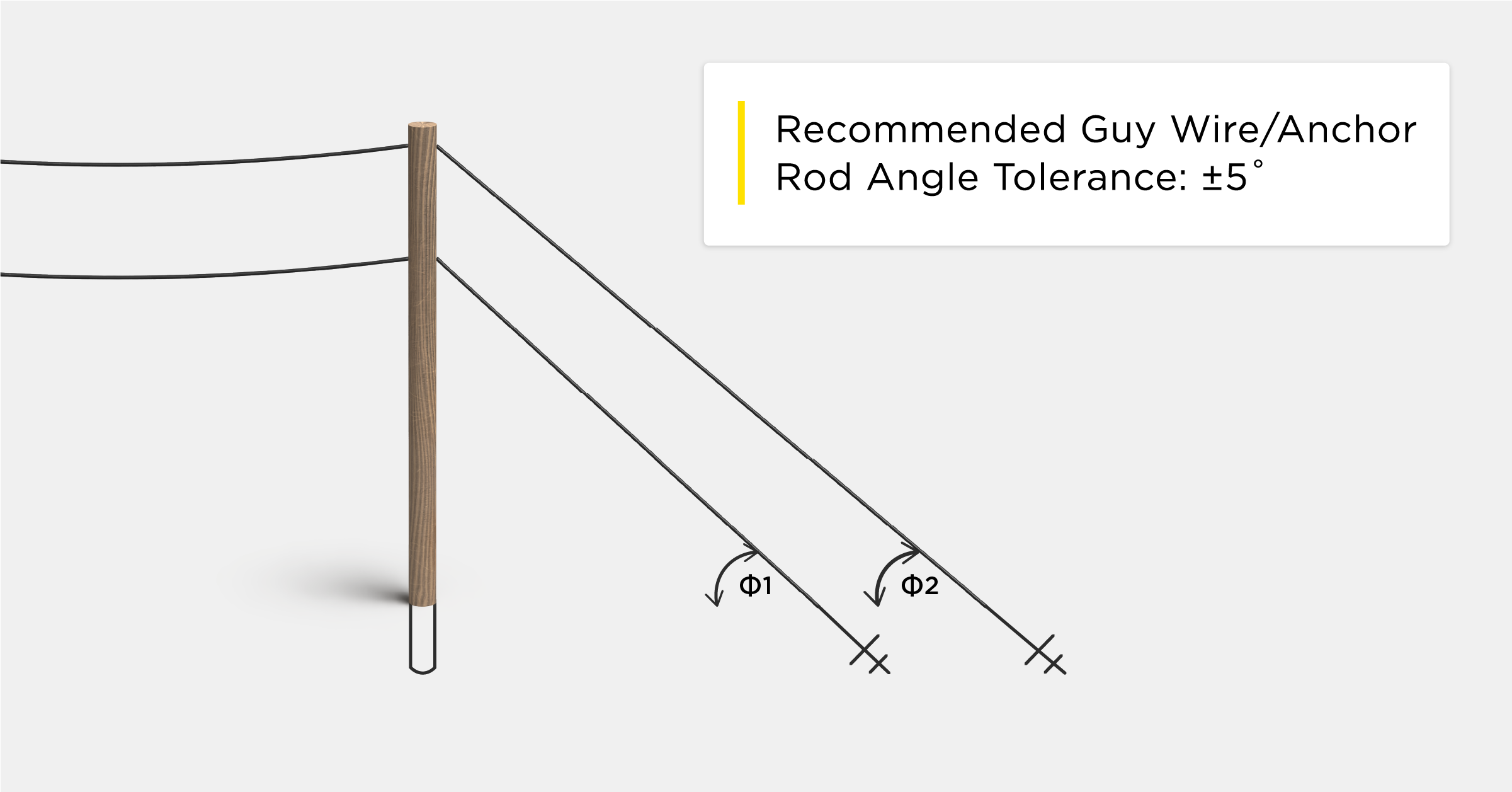

When anchors go sideways The bending stress and lateral load induced when an anchor is misaligned...

Written by Gary L. Seider, PE

A common question asked by engineers and contractors is “how does anchor spacing affect uplift...

Written by Gary L. Seider, PE

This post was originally published on January 3, 2020 and updated on June 21, 2022.

Written by Sarah Banks

Anchors have been used by utilities since 1912. It was then that a young Albert Bishop Chance (age...

Written by Gary L. Seider, PE

Underground corrosion is a function of several factors, which makes it difficult to give a...

Written by Gary L. Seider, PE

Every application is different, but they often have something in common with other applications. We...

Written by Timothy See Thoe

At Hubbell Power Systems, Inc. (HPS), we are committed to providing our customers with outstanding...

Written by Tim Staelens

The torque-to-capacity relationship for helical anchors and piles is an empirical method originally...

Written by Tim Staelens

Predicting the holding capacity of an anchor can be difficult due to soil variations at different...

Written by Tim Staelens

The reliability of our overhead power and communication lines is as important today as ever before....

Written by Tim Staelens

Caliche is best described as salt-cemented sand. Naturally occurring in arid and semi-arid regions,...

Written by Tim Staelens

It is well-documented that the best method for predicting the capacity of helical piles and anchors...

Written by Tim Staelens

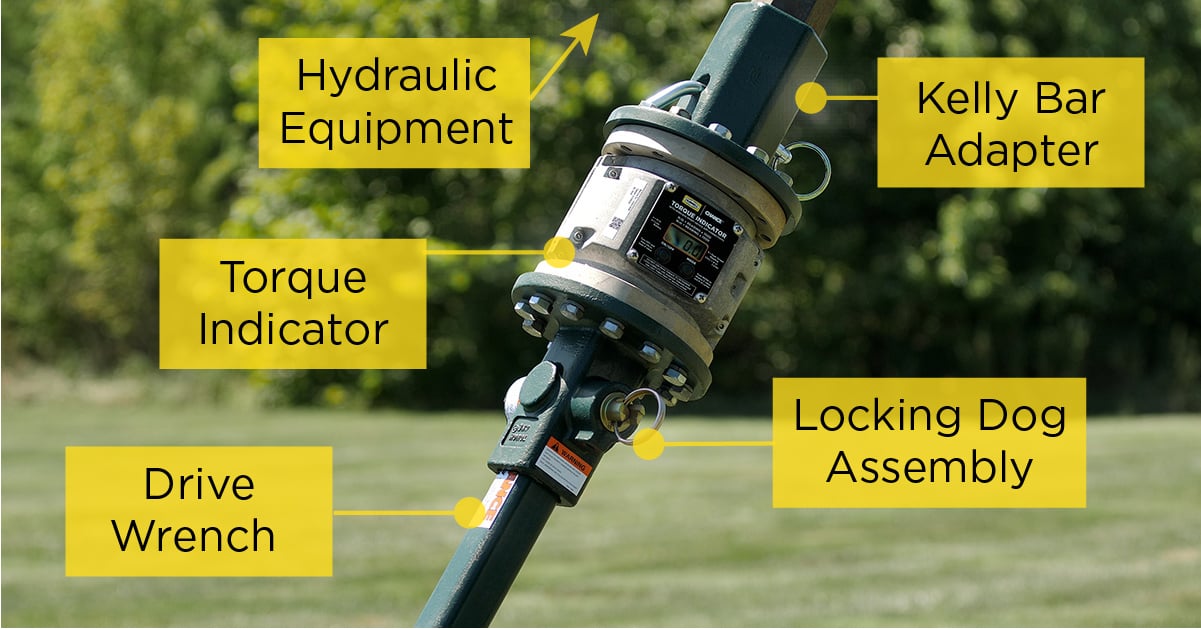

Once all safety concerns have been addressed, attach the Kelly bar adapter and installing tool...

Written by Tim Staelens

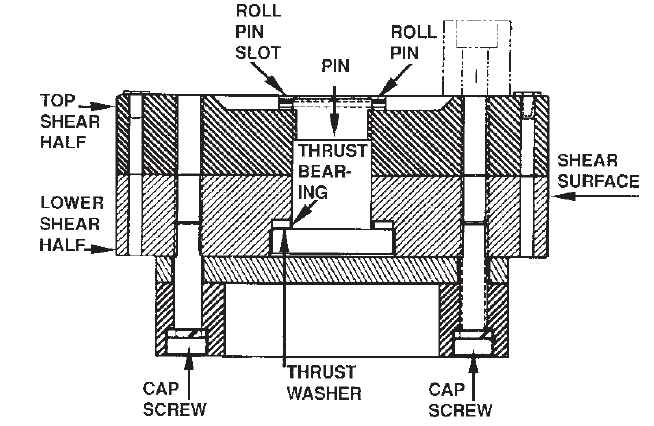

As with most mechanical devices, CHANCE® anchor-installing tools periodically require maintenance...