- Hubbell Power Systems Blog

- Insulators

Insulators

Written by Joseph Harris

What does it take for a product to become a market leader in the electrical power market? It takes...

Written by Jeff Butler

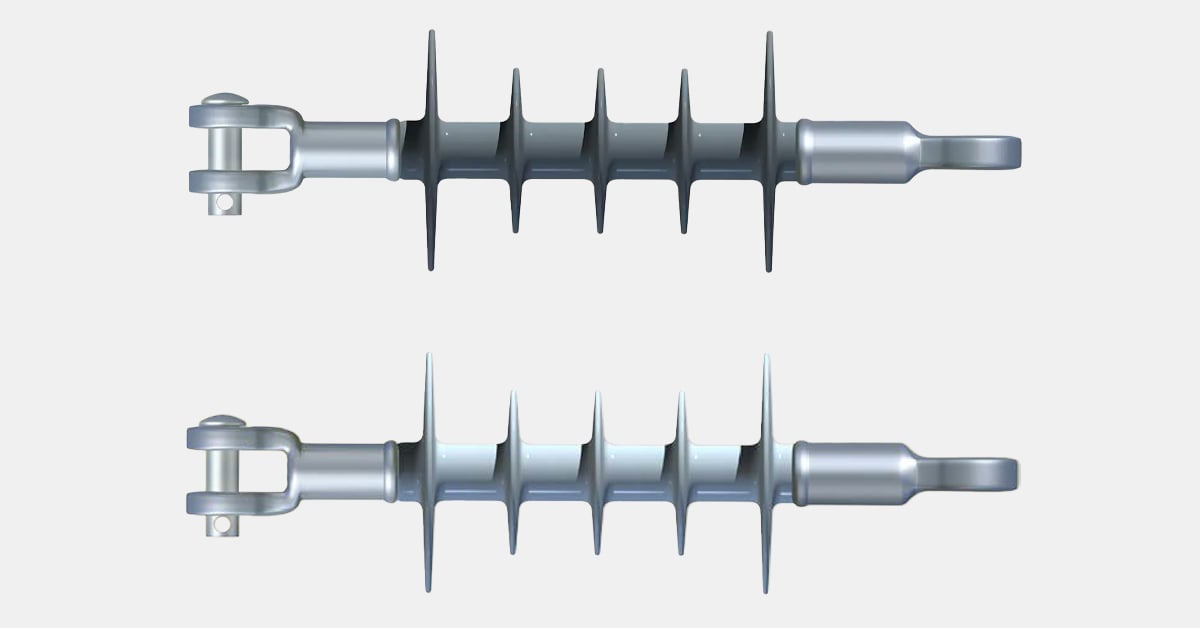

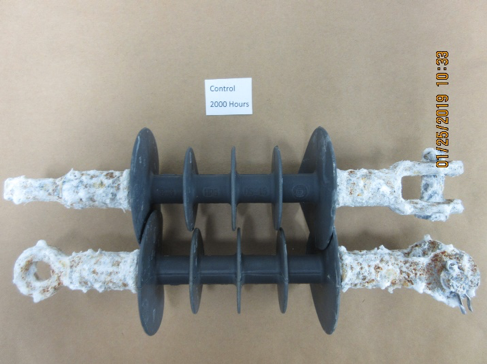

Looking at polymer insulators, we’ve considered several factors that determine superior material...

Written by Jeff Butler

Today’s fourth generation Quadri*Sil™ polymer transmission insulator has an expected service life...

Written by Jeff Butler

Enhanced Silicone Polymer

Written by Jeff Butler

We talked previously about the science behind compounding superior silicone rubber for polymer...

Written by Jeff Butler

Not all silicone is the same. It’s a chemistry thing. Silicone rubber is a mixture of many...

Written by Jeff Butler

Welcome to the first of our six-part informational series on the polymer high-voltage insulators...

Written by Jeff Butler

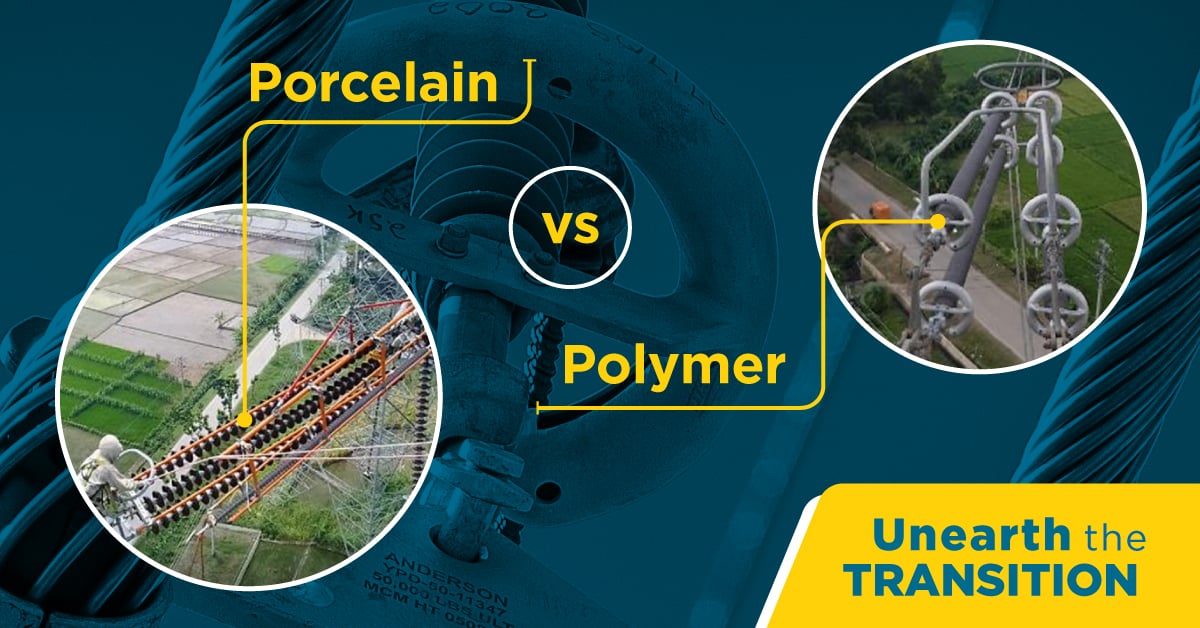

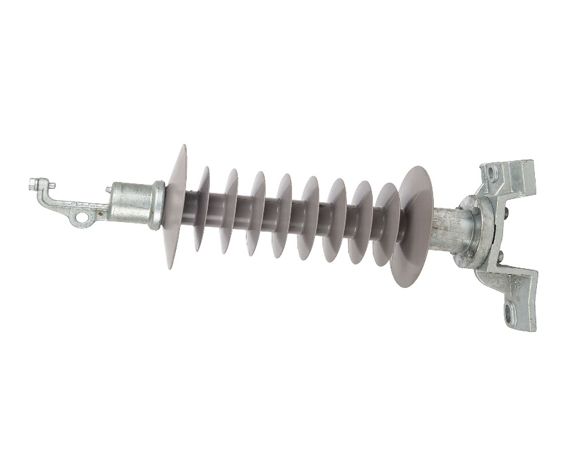

Brief History of Materials Used in High Voltage Insulator Construction As the power grid continued...

Written by Jeff Butler

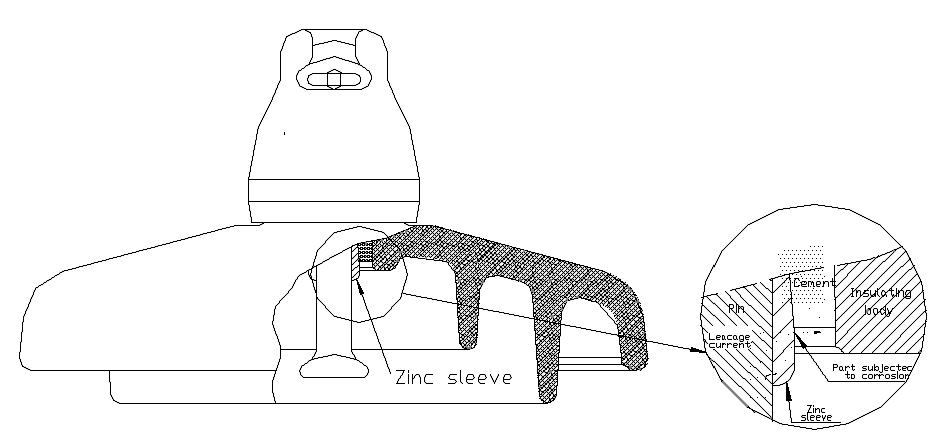

TDG or thermal diffusion galvanizing is a method of applying a uniform, sacrificial, zinc and iron...

Written by Robert Ransone

The Insulators Business Unit at Hubbell Power Systems, Inc. strives to provide innovative solutions...

Written by Robert Ransone

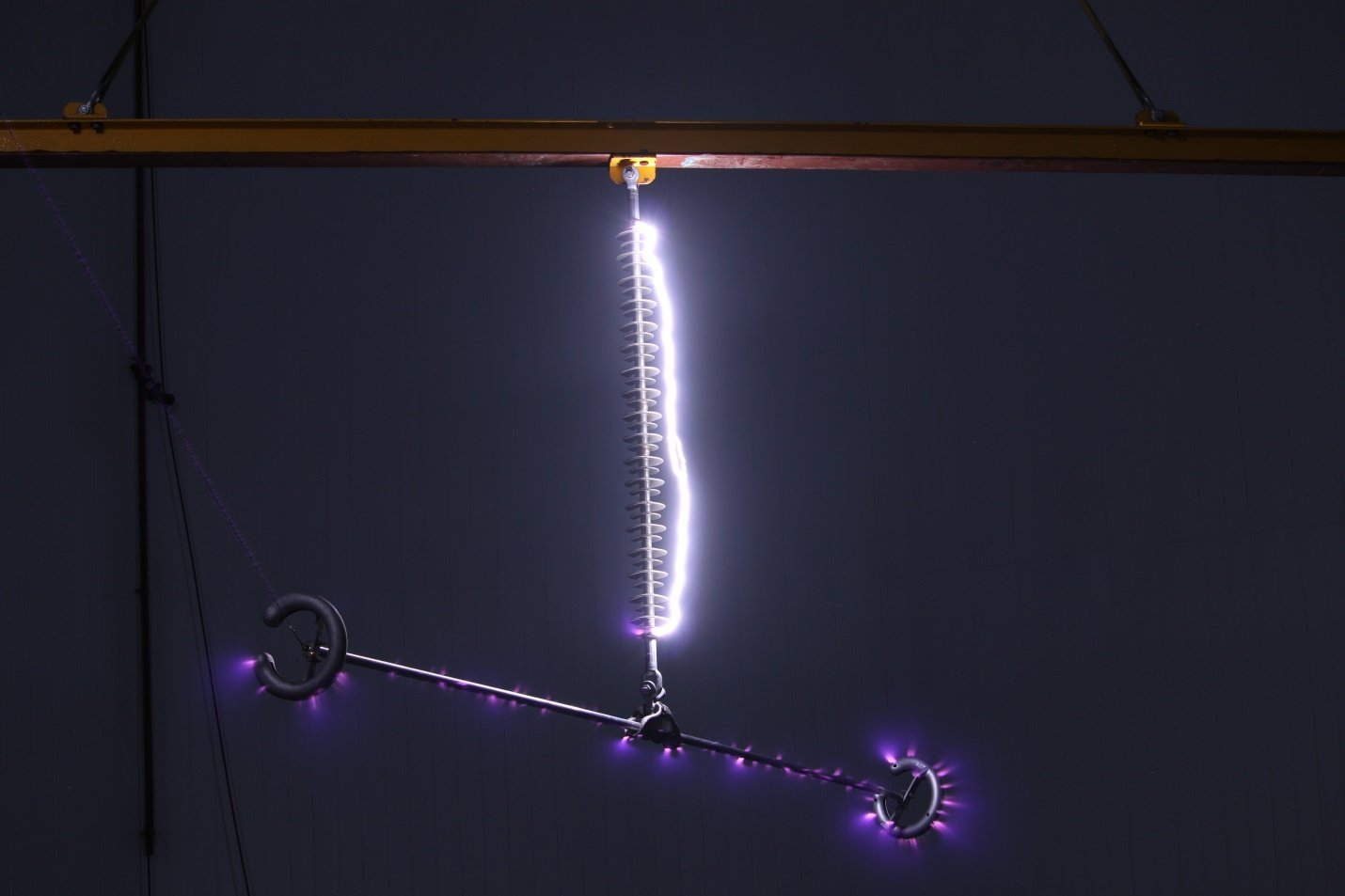

In physics, the glow and audible event occurring when an insulator is exposed to excessive voltages...

Written by John Schonewolf

To support design and development activities, we maintain a fully equipped electrical and...

Written by Robert Ransone

Toughened glass bell insulators are easily identified through the application of color bands on the...

Written by Robert Ransone

When designing a high voltage transmission line utilizing toughened glass bell insulators,...