- Hubbell Power Systems Blog

- Lineman grade tools

Lineman grade tools

Written by Brian Moegling

Barry D.E.W. Line Insulating Tag Lines have many applications during live-line maintenance....

Written by Robin Stephens

Mechanical hoists, both nylon strap and chain types, are useful devices in electrical utility...

Written by Joseph Cardona

When an energized conductor or piece of equipment must be supported or moved for maintenance, line...

Written by Joseph Cardona

Everyday Linemen across the world use CHANCE Hotsticks (live-line tools) to perform maintenance on...

Written by Brian Moegling

With the 2022 International Lineman’s Rodeo officially in the books, let me express gratitude on...

Written by Brian Moegling

As global leaders in tools and training for live-line maintenance of electrical transmission...

Written by Frank Riffle

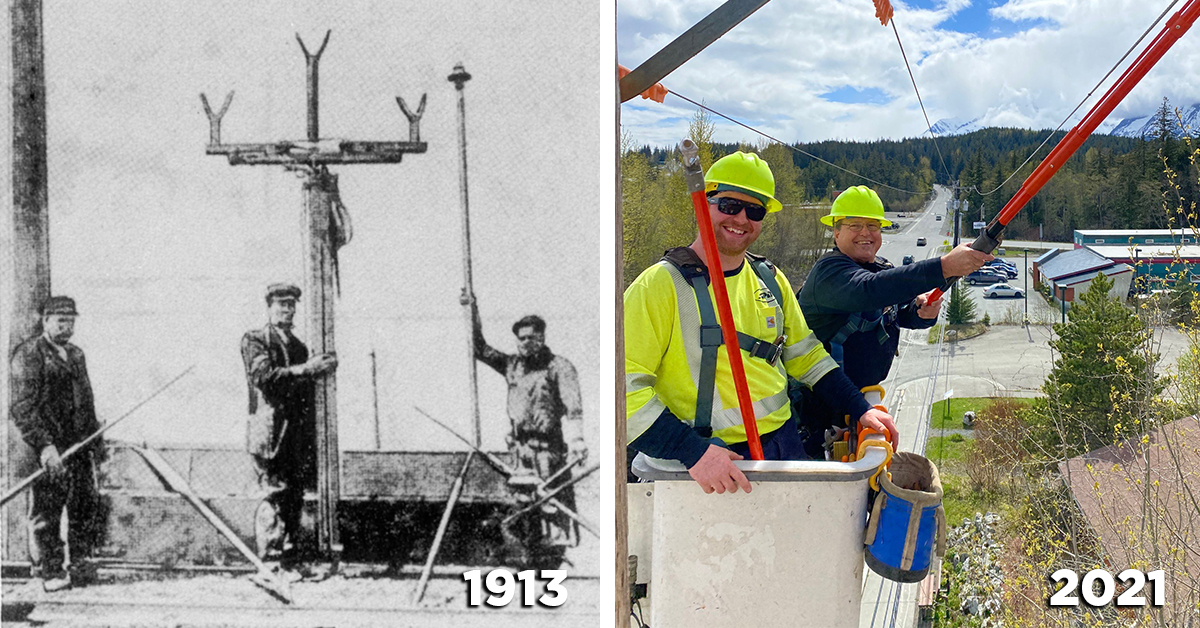

Hot line maintenance began when disconnect sticks were first used to open energized disconnect...

Written by Frank Riffle

Every day, linemen across the world perform energized line maintenance using a variety of personal...

Written by Frank Riffle

CHANCE® Insulated Jib Extensions attach to the material handlers on bucket trucks and aid linemen...

Written by Joseph Cardona

In the event of a fault, current will seek any and every available path to ground during...

Written by Joseph Cardona

CHANCE® Personal Protective Grounding Sets are an important tool for Linemen to use during...

Written by Joseph Cardona

Temporary protective cover-up is a common piece of personal protective equipment used by linemen...

Written by Kyle Broyles

I think I can speak for us all, it was great to be back!

Written by Joseph Cardona

Temporary protective ground sets are one of the most important pieces of personal protective...

Written by Joseph Cardona

In many cases, a line worker is faced with several daily tasks which require them to use a...