- Hubbell Power Systems Blog

- Joseph Cardona

Joseph Cardona

Written by Joseph Cardona

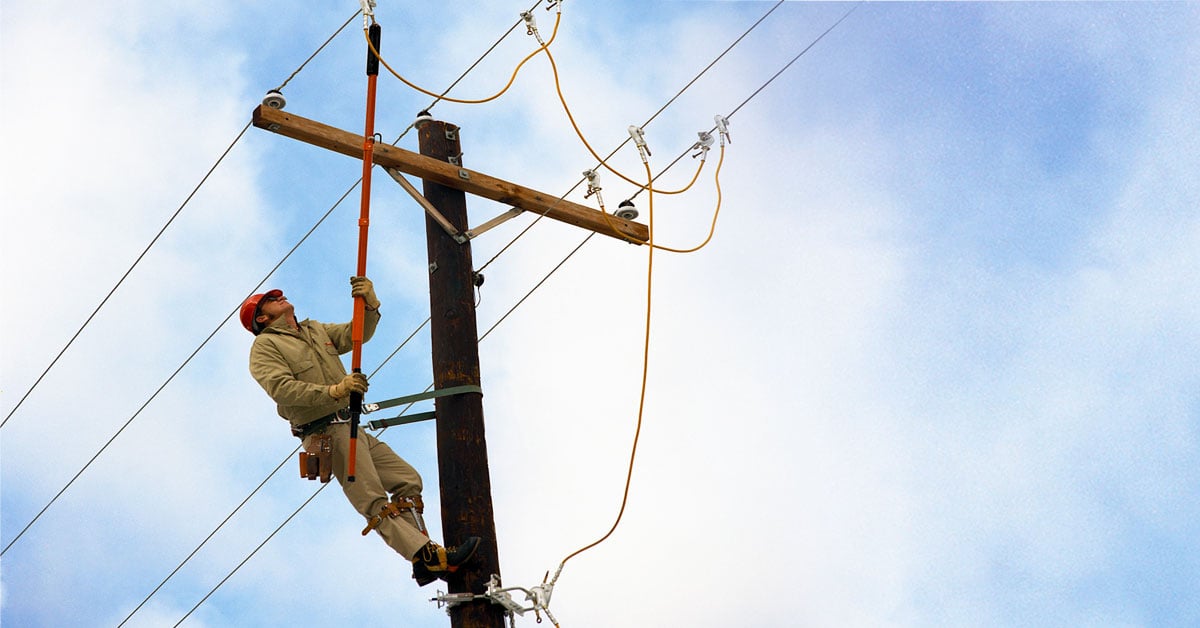

Everyday Linemen across the world use CHANCE Hotsticks (live-line tools) to perform maintenance on...

Written by Joseph Cardona

In the event of a fault, current will seek any and every available path to ground during...

Written by Joseph Cardona

CHANCE® Personal Protective Grounding Sets are an important tool for Linemen to use during...

Written by Joseph Cardona

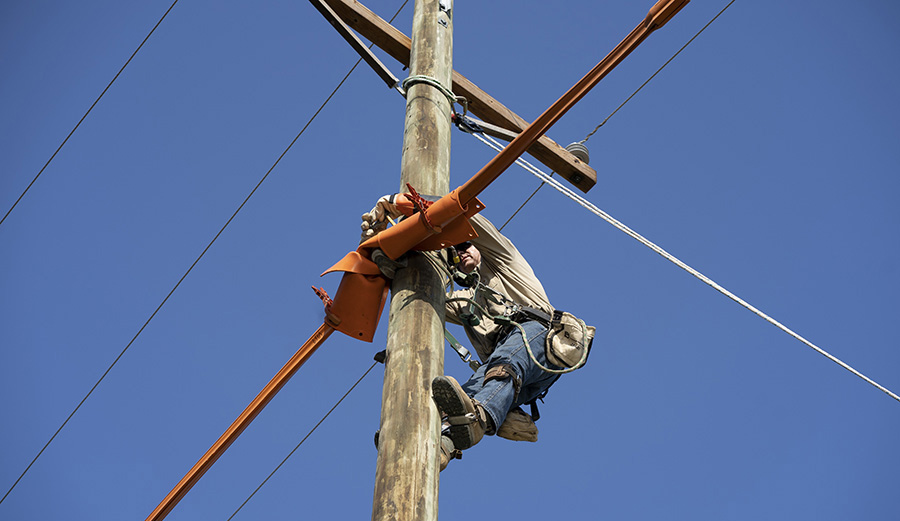

Temporary protective cover-up is a common piece of personal protective equipment used by linemen...

Written by Joseph Cardona

Temporary protective ground sets are one of the most important pieces of personal protective...

Written by Joseph Cardona

In many cases, a line worker is faced with several daily tasks which require them to use a...

Written by Joseph Cardona

During line work, it is commonplace for lines to be de-energized and grounded for worker protection...

Written by Joseph Cardona

To maintain worker safety while performing de-energized and grounded line maintenance, two...

Written by Joseph Cardona

CHANCE® Personal Protective Ground Sets are an important tool for lineworkers to use during...

Written by Joseph Cardona

What is Step and Touch Potential? While performing energized or de-energized line work, there are...

Written by Joseph Cardona

Energized line maintenance is a popular option for working on power lines. Two common methods for...

Written by Joseph Cardona

Hard Plastic vs. Rubber Cover-Up Equipment Deciding which cover-up equipment is best for the job...

Written by Joseph Cardona

Insulating rubber blankets for energized line maintenance come in a variety of sizes, classes and...

Written by Joseph Cardona

Download the Cover-up Care Guide Here are five ways linemen can ensure their temporary protective...