Guy Anchor Testing Procedure

Predicting the holding capacity of an anchor can be difficult due to soil variations at different depths and different structure sites. Continue reading to understand how to ensure the integrity of your guyed structures.

Written by Tim Staelens on May 20, 2020

Predicting the holding capacity of an anchor can be difficult due to soil variations at different depths and different structure sites. It is critical to understand anchor capacity to ensure the integrity of your guyed structures.

Predicting the holding capacity of an anchor can be difficult due to soil variations at different depths and different structure sites. It is critical to understand anchor capacity to ensure the integrity of your guyed structures.

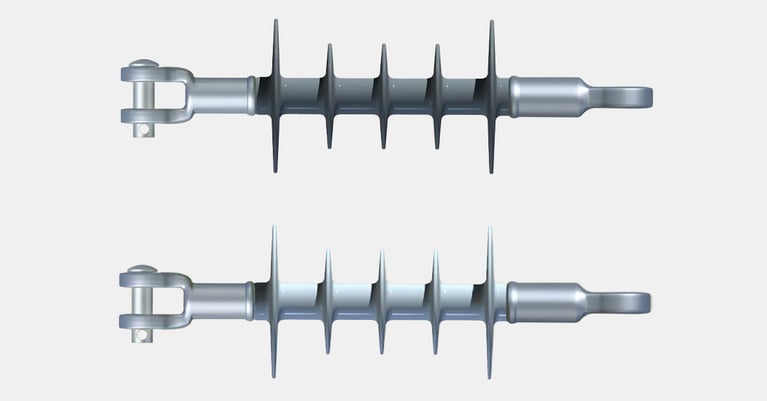

Measuring torque during the installation of a screw anchor is a reliable way to predict the holding capacity, but a pull test gives you the added assurance the anchor will hold during high load conditions.

Testing of guy anchors falls into two categories, Pre-Production and Production Tests

The anchor test proposal shall be in general conformance with ASTM D-3689, and shall provide the minimum following information:

For more information on Load Test Procedures, click on this link to see the Anchor Load Testing guide.

Sign me up to receive the latest posts from the Hubbell Power Systems Blog to my email.