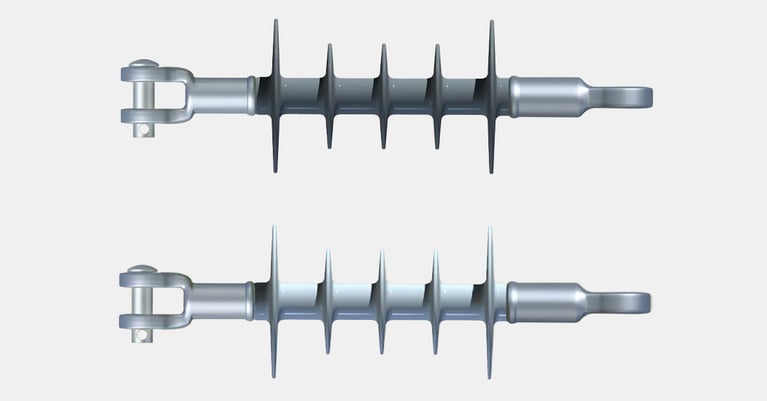

TDG or thermal diffusion galvanizing is a method of applying a uniform, sacrificial, zinc and iron alloy coating using a metallurgical vapor diffusion process. Hubbell Power Systems, Inc. has investigated this method for use in the coating of end fittings for distribution insulators and the results show improved performance over traditional hot dipped galvanizing (HDG). In addition to improved anti-corrosive performance, TDG is a more environmentally friendly process due to its virtually zero-waste system.

Testing the Thermal Diffusion Galvanizing or TDG Method

Governing insulator standards ANSI C29, as of now, do not define standard prototype or quality conformance tests due to a change in galvanizing method. Because of this, Hubbell Power Systems treated the TDG end fittings as a different material and went through the prototype test requirements per the relevant insulator standards. In addition, samples were tested in a salt fog chamber according to ASTM B117 and mechanical testing of effective crimp trials were conducted to ensure process capability.

For change of metal end fitting materials in polymer distribution suspension insulators, also known as PDIs, the following prototype tests were required per ANSI C29.13:

- Water Penetration Test

- Power Arc Test

- Tensile Load Test

- Torsional Load Test

- Thermal Mechanical Test

Testing was completed primarily at the ISO 17025 accredited Hubbell Power Systems high voltage test facility in Wadsworth, OH and all testing passed successfully.

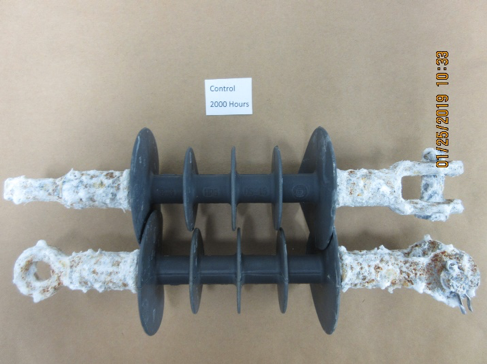

The anti-corrosion performance of the samples from the ASTM B117 salt fog chamber located in our Centralia, MO lab is shown below by comparing standard HDG end fittings and TDG end fittings. After 4,000 hours of salt fog exposure, the HDG samples are thoroughly covered with deep penetrating corrosion, while the TDG samples show corrosion only in limited areas with minimal penetration.

TDG's Improved Performance Over HDG

Hubbell Power Systems has learned that not all TDG treatments are the same. Like so many of our other critical process, it is important for Hubbell to use our in-house capability where we can ensure consistent controls over target coating thickness, a 2 sealant application process and routine QA testing to verify proper penetration of the zinc material. With years of research and thousands of hours of testing, Hubbell Power Systems stands behind TDG’s improved anti-corrosive performance over HDG to combat the harsh environment and provide the necessary endurance of your critical distribution infrastructure.