Understanding Classes and Types of Rubber Insulating Blankets

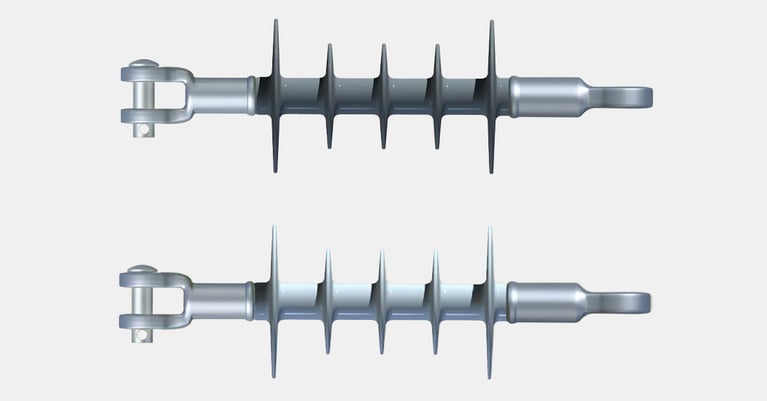

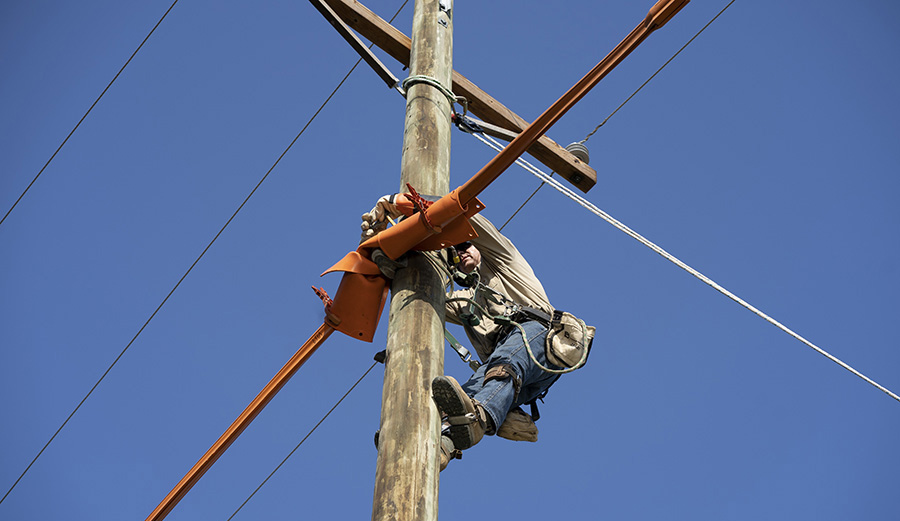

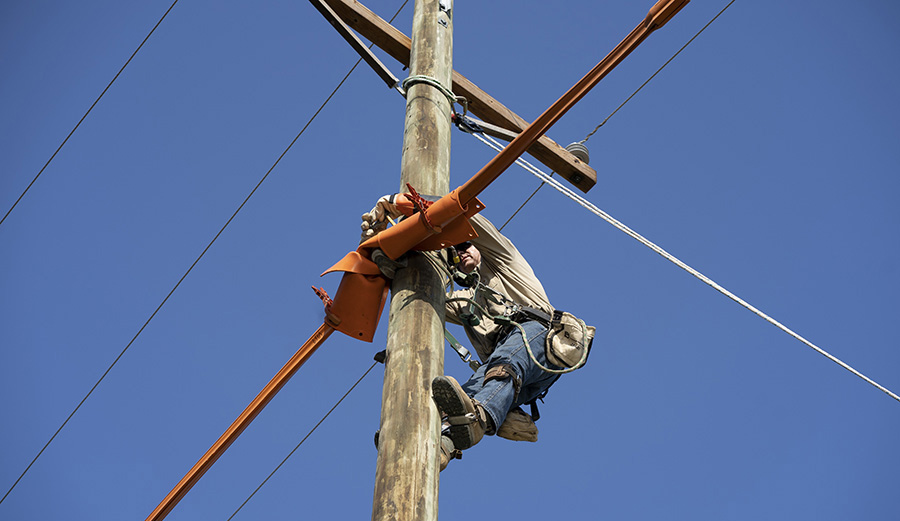

Insulating rubber blankets a type of cover-up used by linemen for energized line maintenance. They come in a variety of sizes, classes and types, described in ASTM D1048.

Written by Joseph Cardona on May 26, 2020

Insulating rubber blankets for energized line maintenance come in a variety of sizes, classes and types. Each Class of insulating blankets has its own maximum use and testing voltages, as described in ASTM D1048 (see Table 1). The higher the class rating, the higher maximum the voltage rating is for the insulating blanket.

Table 1: Proof/Design=Test/Use Voltage Relationship

| Class of Insulating Blankets | Nominal Maximum Use Voltage Phase-Phase, ac, rms, max | AC Proof-Test Voltage, rms V | DC Design-Test Voltage, avg, V |

| 0 | 1 000 | 5 000 | 20 000 |

| 1 | 7 500 | 10 000 | 40 000 |

| 2 | 17 000 | 20 000 | 50 000 |

| 3 | 26 500 | 30 000 | 60 000 |

| 4 | 36 000 | 40 000 | 70 000 |

(Table 1 reproduced, with permission from ASTM D1048, copyright ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428.)

The difference between Type I and Type II blankets is the material that they’re made from. The most important considerations when deciding which type of blanket you need are flexibility and ozone resistance. If you need:

The synthetic EPDM rubber can trace its roots back to World War II when there was an inability by the US to source natural rubber in Southeast Asia. Type I CHANCE blankets are made from a synthetic latex rubber and have excellent flexibility. Type II blankets are made from EPDM rubber, which has excellent corona resistance. The Type of blanket you select is a personal preference and does not affect voltage rating.

Hubbell Power Systems offers a variety of CHANCE® ASTM D1048 designed and tested rubber insulating blankets. CHANCE rubber insulating blankets are intended for secondary incidental brush contact and are designed to temporarily cover up energized line equipment for no more than 72 hours. Each blanket is visually inspected, electrically tested for 3 minutes, and date stamped prior to shipment. The larger blankets (36” x 36”) are sold in quantities of 6 and the smaller in quantities of 12 (22” x 22”). HPS also offers a bulk pack option for Class 4 orange solid (C4060346BP) and slotted (C4060348BP) blankets which includes 100 of them.

CHANCE rubber insulating blankets must be electrically tested every 12 months per ASTM F479. Prior to daily use, the blankets should be free of contamination and visually inspected for damage. Inspecting for damage can be accomplished by rolling the surface of the blanket per ASTM F1243. Stressing the surface of the blankets can open and display cuts or pinholes that may have closed. If the surface of the blanket is dirty, it can be cleaned with a clean cloth wipe and alcohol prior to use. When not being used, blankets should be stored rolled up in storage canisters or laid flat. They should be placed in a cool, dry location away from heat, ozone, and sunlight.

For full care instructions, click here.

Click here for current CHANCE rubber insulating blanket offerings and accessories including pins, buttons and storage canisters.

Sign me up to receive the latest posts from the Hubbell Power Systems Blog to my email.